The main and obvious difference between the Exmo and all the other monocoque cars sold by Robin Hood Engineering (RHE) is the front suspension design.

Here the McPherson strut design of the donor Sierra is employed, albeit with a narrower and shorter strut grafted into the existing Ford parts. However, there are some snags, firstly some parts involved are not "off the shelf" and were a special purchase by RHE, secondly the top mounting point of the suspension has issues.

An Exmo kit, built using the original parts and instructions, will almost certainly develop the following problems as it is used on The United Kingdom's silky smooth highways.

In practical terms the owner then faces the following problems in order to keep the car roadworthy.

If you want to see a list of links to the forum posts that have accumulated on Exmo front suspension over the years, then click here.

If you are interested in the going into more detail, keep reading.

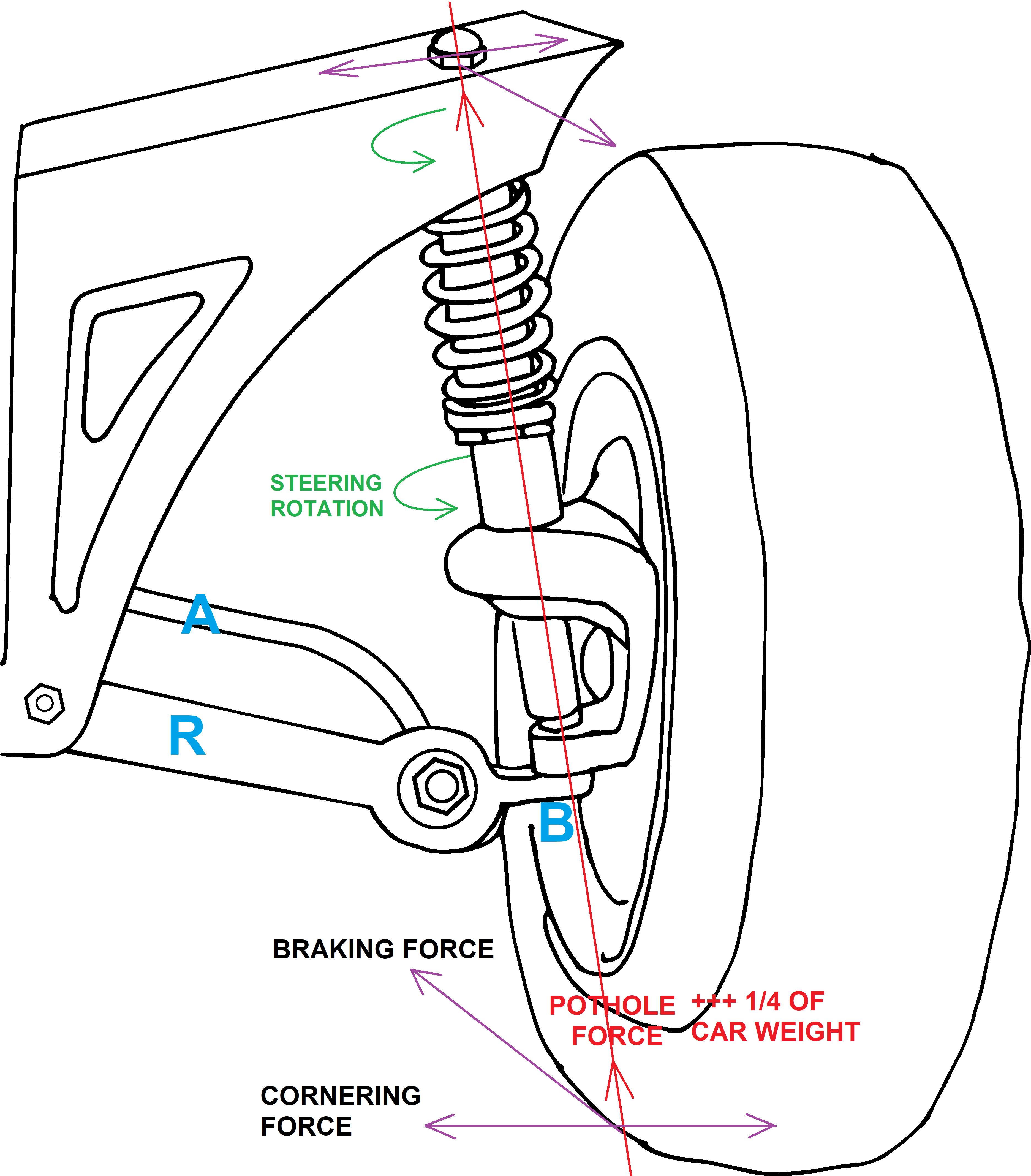

The ball joint (B) lets the strut swivel at its base. The ball joint itself is prevented from moving left or

right by the radius arm (R), and from moving forward or backward by the anti roll bar (A). Rubber

bushing is used to connect these, it alows small "compliant" movement which absorbs vibrations

and some flexing.

The ball joint (B) lets the strut swivel at its base. The ball joint itself is prevented from moving left or

right by the radius arm (R), and from moving forward or backward by the anti roll bar (A). Rubber

bushing is used to connect these, it alows small "compliant" movement which absorbs vibrations

and some flexing.

Deteriorization due to wear or age in any of these bushes will give rise to large movements that cause metal to metal contact (bangs) and because the ball joint, which can also wear, moves around problems such as uneven tyre wear, juddering while breaking, and in bad cases, wandering. These are "normal" problems that can happen to all cars with this type of suspension design and the Exmo uses the off the shelf Ford Sierra ball joint and bushes, so repair is not a problem.

The ball joint is a fulcrum in the line connecting the bottom of the road wheel and the top mount of the strut thus forming a lever. Any force acting on the roadwheel at its contact point with the road will be transmitted to the strut top.

Imagine a worst case, where the car hits a pothole while braking on a tight bend. The strut is compressed decreasing the lever length, there is a force at right angles to the direction of the car from cornering and a force in line with the direction of travel from the breaking, and a vertical force along the line of the strut from both the weight of the car and the impulse of hitting the hole. All this arrives at the top mount which still needs to rotate freely about the strut axis for steering.